the series’ name is a portmanteau of ‘co-creation’ and ‘porcelain’

view of the parts’ printing process

KEEP UP WITH OUR DAILY AND WEEKLY NEWSLETTERS

happening now! SICIS brings the intricate art of mosaic and innovative materials to interior design, harmonizing every element — from furniture to surfaces — for complete environments.

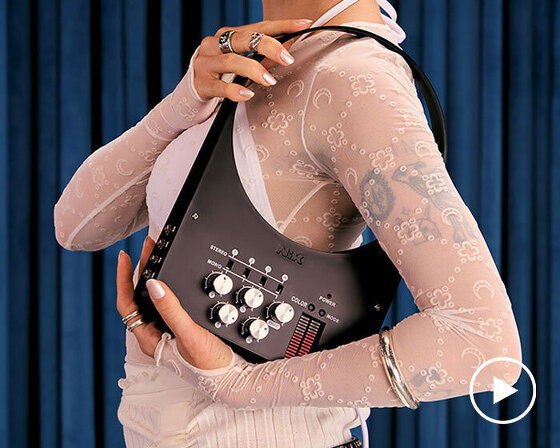

a bluetooth-enabled speaker bag and a functioning 4-channel mixer bag are part sound system, part sculptural accessory.

connections: +300

the dancing bench at concéntrico festival is part of the studio's series exploring how familiar objects can be recharged through unexpected mechanics and sensory experiences.

connections: +540

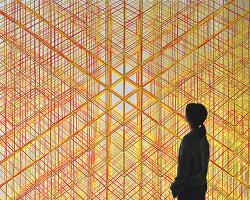

formation, the italian design studio's first US gallery exhibition, is now on view at friedman benda's new york space.

planned for a september 2025 release, the redesign is present in iPadOS, macOS, watchOS, tvOS, and CarPlay to make all the devices uniform.

connections: +190